Effective asset management has become a buzz word in wind. We talk about it a lot. We peer at it from various lenses. And we pick at it from dawn to dusk. We get it. As renewable energy developers, managers, and consultants, we want answers: what really makes for effective wind asset management services?

Today, as we round up a decade of actively campaigning for renewable energy, onshore wind farms have become one of the cheapest sources of power. A recent report by Bloomberg NEF revealed that the levelized cost of energy produced by onshore wind projects fell 9% in the second half of 2019.

As more results of this global clean energy marathon roll in, the search for efficiencies in wind farm asset management services only intensifies.

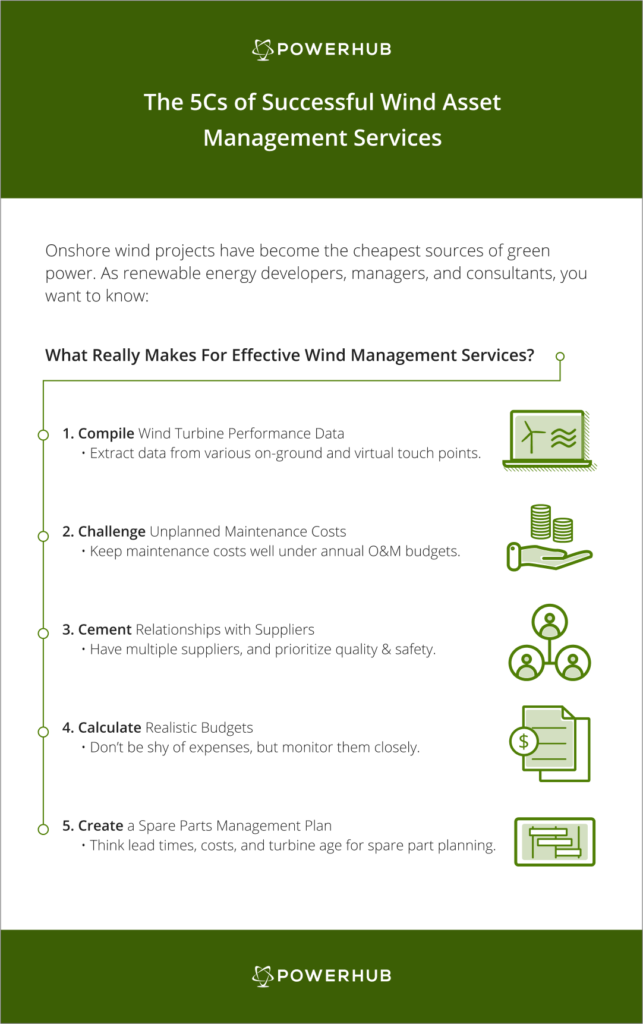

5 Cs That Will Make Your Wind Asset Management Services Reap Results

Compile Wind Turbine Performance Data

The starting point of every efficiency analysis is data. As a smart wind farm asset manager, you should always be on a hunt to gather performance figures for the turbine fleets under your guardianship.

Try to be proactive with site visits. Maintain open and regular communication with site managers so you’re always in the loop for what’s happening on the ground.

And finally, ensure that the software you use for wind asset management services is integrated with your monitoring system. Doing so will mean that you always have quick access to weekly, monthly, and quarterly performance figures.

Challenge Unplanned Maintenance Costs

Whether you like it or not, in the world of renewables, things hardly go as planned. Wind is a force of nature – one that often asserts itself strongly in the face of even the best laid out management and maintenance plans. However, what will keep you on track for performance is challenging and questioning unplanned costs.

Let’s say your maintenance crew is carrying out overtime jobs, and there’s a backlog in service schedules. In this case, your total maintenance costs will likely be higher than the annual budget. What’s causing this backlog? How can it be fixed? Again, trends and insights on wind farm performance will help you answer these questions in a timely manner.

We’ve previously talked about essential key performance indicators for wind asset management services in great detail on the PowerHub blog. These indicators take into account various factors like corrective vs. preventive maintenance, response time, and scheduled compliance to indicate the overall health of the turbines.

Cement Relationships with Suppliers

Supplier relationships are a crucial component of successful wind asset management services. And it’s always best practice to have good ties with various suppliers for major maintenance work.

Doing so induces flexibility in your management and maintenance schedules. It will also help you balance expenditure with lost revenue due to downtime.

Supply chain fluctuations are common in the renewable industry because a sizable chunk of spare parts, especially for turbines, is imported from cheaper suppliers.

Moreover, since a surge in the global demand for wind power, manufacturers and suppliers have been pressed for shorter lead times, lowered costs, and higher than normal production.

This brings us to another important disclaimer: while it’s important to manage costs, nothing trumps maintaining high quality and safety standards. This is one of the biggest considerations you should have in mind when building valuable supply chains.

Calculate Realistic Budgets

Whenever we talk about budgeting for asset management, we always follow it up with a note on being realistic. They really go hand in hand. While CAPEX costs are dependent on a host of externalities, OPEX definitely comes under the renewable asset management scope.

We always advise wind farm asset managers to set a realistic annual OPEX budget and then monitor it with a hawk’s eye. It’s okay to have variances. Just be sure to question them, and be proactive incase costs start rising.

Create a Spare Parts Management Plan

Spare part management for wind projects is quite different from other renewable projects. For one, turbine parts are large and bulky. These have to be ordered, and transported to far-flung wind farms safely. Second, these parts are super expensive. Which makes planning ahead so much more important.

Therefore, creating a well-planned strategy is essential. As a first step, you should have an agreed-upon timeline. When are parts needed? When will maintenance be scheduled?

Next, what can really help optimize this plan is categorizing spare parts by lead time. Great minds in wind suggest that parts with long lead times should be held close to the farm.

On the other hand, those that have shorter lead times – but are more expensive – can be stocked with suppliers you have good relations with. In case your wind project has a higher percentage of older turbines, managing these parts and their lead times becomes all the more necessary.

Compliment Your Strategy with Smart Asset Management

Successful wind farm asset management services are dependent on the tools and software you employ for daily activities.

A smart platform should provide the right level of technical and financial support to your wind portfolio. Only then will you be able to leverage it, and reap results with the 5Cs.

So, how intelligent is your wind farm asset management software?