Renewable Energy Spare Part Management

Ever put off going through your to-do list because you don’t know where to start? Or have trouble choosing off of a menu at a restaurant because there are simply too many options? If not, then you’re a better person than I. It’s called the Paralysis of Choice, that feeling you get when there are too many items or decisions in front of you to focus on just one, and it’s more common than you likely think. Especially when it comes to renewables and spare parts.

Let me explain.

If you had, let’s say, one solar farm and one wind turbine, dealing with spare parts would be a breeze (pun intended). Your extra inverters, circuit boards, panels and other parts could be managed on a single spreadsheet. You can easily see how many you have, compare to thresholds, see warranty expiry dates, and more.

Now let’s say you have 10 projects. Or 100. Or 200! How easy is that spreadsheet to manage now? This is a multi-tabbed, out-of-date mess that always takes days to review and insure it’s up to date before sharing or making decisions. How do you know which project needs your attention now? How do you focus?

This isn’t a wind issue, or a solar issue, or a hydro issue. It’s a challenge we see clients from every technology face. At the end of the day, the ultimate goal of spare parts management is to be able to make smart business decisions, with the most up to date information possible, without having to review it on a project-by-project basis. And this is difficult because of the sheer volume of things.

You need a tool and a process to track and manage items, and importantly, to keep track of re-order thresholds, so that you can—here comes the biggest challenge of all—have spare parts available when you need them. The alternatives are paying premiums to get parts shipped in an expedited way or worse…risking the system staying down for an extended, and unnecessarily long, time.

(If you’re not in the renewables business yet, and don’t know which thresholds I’m referring to: most operators are generally contracted to have a certain amount of spare parts available for a site.)

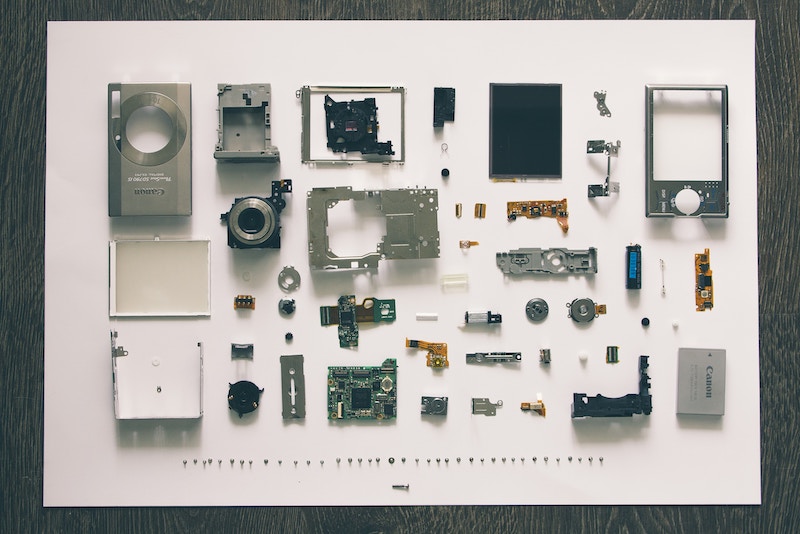

The First What – What counts as a spare part?

This is actually a more contentious issue than you might think. Some people include in “spare parts” what others call “incidentals” or “consumables”, such as small fuses, brushes, plugs, and filters. The reality is that you have to manage these items, regardless of what you consider consumables or not. Both have a cost, and everything needs to be on hand when needed— Typically, small, inexpensive, common items with low lead times are considered consumables, as hopefully they’re readily available without a premium at multiple suppliers.

Spare parts that most can agree are important to track are the larger, more expensive items that have potentially longer lead times, and frequently, few suppliers. In the case of solar, these, typically, are inverter components, extra circuit boards, big expensive fuses for high or mid voltage, panels, combiner boxes, and dozens of other pieces.

If you’re operating wind assets, you have an even bigger challenge: most of your parts are fairly large and expensive, with long lead times. You absolutely have to track how far away the parts are, how long the order times are, and how quickly you can get it to the site—on top of everything else.

Aside from being tracked for use, these items also need to be tracked in terms of appreciable size, and appreciable value (more on that below).

Two: What is the importance of thresholds?

As I explained above, most projects have an explicit obligation to maintain certain spares available, due to loan agreements, permit agreements, or interconnection agreements, for instance. Some projects, however, have a more implicit obligation, where the requirement is to ensure uptime or availability, and as a result, it’s important to ensure that they have a certain amount of spares available. If you’re not doing a great job managing spare parts for the project(s), the bank, utility, regulator, or even project equity, may have recourse. That could be expensive, and even change your rates, or up your insurance requirements.

The most important thing is to have a re-order threshold, which is the moment your risk analysis suggests you should be reordering. That is the key. Receiving product may take time, and you may have risks associated with not having those spares on site. One mismanaged part could see your whole system go down. Those are the risks you’re trying to mitigate with spare parts management.

Three: What do warranties have to do with spare parts management?

Warranty management is always a consideration in spare parts management.

When you’re using available parts to sub out old or broken pieces, you’ll likely want to manage any warranties—so get things that are still under warranty in place sooner than later.

But what do you know about those warranties? Does an item’s warranty start upon delivery to site? Does it start upon install? Does it start upon receipt to distributer? Most importantly, which one has a shorter warranty period? That item should be used first, right?

Even if the answer is easy and you know which spares item needs to be installed next, how do you find it? I can guarantee that there are few to no projects that have a proper FIFO or LIFO inventory management practices in place. It’s likely there is a pile or box somewhere in a corner that contains the components, and identifying the component you should be installing is like finding a needle in a needle stack.

Unfortunately, we’ve seen a lot of inverter suppliers disappear, either through bankruptcy, or through the shutting down of business units. This means that a bunch of warranties are now pretty much worthless, and spare parts may be tough to find. The spare components sitting in your inventory suddenly become very valuable, and literally irreplaceable. They’re the only way you can maintain your inverter, should problems arise.

Four: What is the solution to properly managing spare parts in renewable energy?

Two words: Active Management!

Know what you have, how much and why you need it.

This can be as simple as being able to identify all the different makes and models in your fleet, and how many spares you have of each. You should also have a way to identify when you need to order more parts (hopefully automated), so, upon use, something is triggered to remind you to order more. A simple email sent out in a timely manner gives you a leg up, and ensures you are not only compliant with your contractual requirements, but that you also minimize downtime because you have parts on site.

This system can do a lot more than just send emails. It can also track warranty periods, or give you a portfolio-wide view of your spare parts. Just as important as having spare parts is knowing where they are—this knowledge can potentially let you cannibalize one project to keep the other running.

At PowerHub, we recently rolled out exactly this type system. Our inventory threshold module allows our clients to set up their thresholds, have access to a usage form, and report on levels across the portfolio. The users of this module, who are either taking inventory out or adding it in, just fill out these forms, and let PowerHub do the rest. As long a as you set up your thresholds (and you should occasionally re-evaluate these thresholds so they make sense) once your inventory dips bellow that, you will be notified to order more.

That’s it.

No more project-by-project tracking in excel, No more copying and pasting each month from excel to report on it, less downtime risk, more piece of mind.

Want to read up on actually managing the repair process? Check out this article on working with OEMs vs. ISPs.