You’ve done everything you can to build a great project. Even so, your renewable energy assets appear to be underperforming. The numbers aren’t where you expected them to be. What gives?

Like any other energy project, to measure asset performance, you need to have the right sensors to track your equipment’s availability and generation. A meaningful set of weather adjusted KPIs will help you understand where and when your project is underperforming.

Before we proceed, I want you to throw out one legacy assumption: fuel is always present. With renewables, fuel sources are variable and out of our control. Hence, tracking performance against KPIs can be a tad challenging.

So, what do you look for? Where do you look first? When should you back off, and when should you rally your team around solutions?

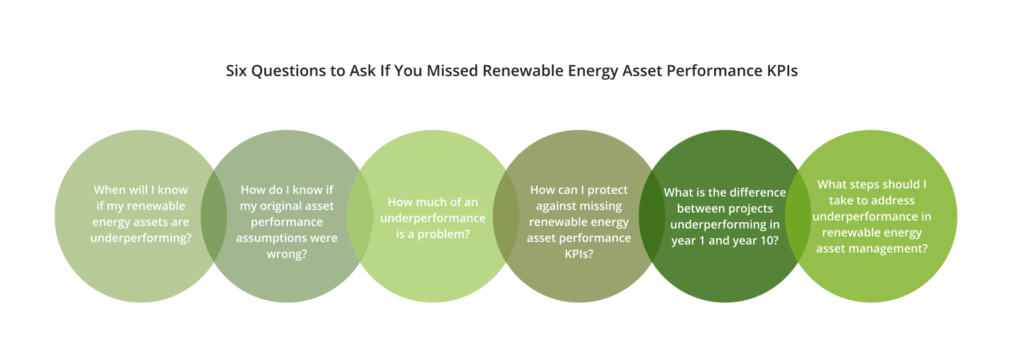

In this discussion, I want to answer six common questions that you should ask when performance isn’t where it should be.

1.When Will I Know If My Renewable Energy Assets Are Underperforming?

That’s a good question but it only gets a question in return; how good is your equipment and how well is it maintained? If you’ve installed great equipment and have a robust tool to analyze it in real time – you should know at any given moment. If not, you should be able to tell a week or two into a month if your renewable energy asset performance is not where it needs to be.

The timing and accuracy of underperformance is largely dependent on the sensitivity of the equipment used. Ultimately, you have to trust your pyranometer, anemometer, flow meter, module temperature sensor, temperature gauge or air density sensor to show you the accurate information. Not to mention, keeping them well-maintained and calibrated.

Aside from general reliability, while some larger-scale projects have powerful equipment that can perform a 15-minute analysis of production, most smaller renewable energy projects do not. If your project is one of these, I suggest drawing average on-site data to properly assess the plant’s underperformance. Using this method, you will need accurate data spanning several weeks, third-party weather reports and an assumption of system losses.

2. How Do I Know If My Original Asset Performance Assumptions Were Wrong?

As I mentioned previously, the most reliable way to check your production assumptions is to look at your project’s weather-corrected performance. If your baselines are off, you have two concerns:

- Did your system perform above or below what you expected? If so, looking at daily figures isn’t too useful, you’ll often have to wait for most of the month to pass to get a solid overview. Even then, if your asset is underperforming, you won’t really know what the exact problem is.

- Was the fuel source available more or less than you expected? This comparison will tell you if the performance problem stemmed from the plant itself or the ever-shifting weather.

Going back to what I said in the previous section, it’s hard to make this judgment on a daily basis. The variability of weather, and of data, is tough. But 1-3 weeks into production (depending on the reliability of your measurements and data), you can generally see where weather and performance are trending.

3.How Much of An Underperformance Is A Problem?

Even if you can safely say that production is off by more than 8-10%, it may not be worth digging into the problem. This loss might be due to changes in weather, which are out of your control. Worst case scenario, even if the problem is with the plant, the ROI on maintenance may actually be worse than the performance deficit.

Hence, I recommend taking a longer-term view of your asset’s lifecycle and focusing on explaining the why of renewable energy asset underperformance. Let’s say that in January you expected an insolation level of 100 but you get a 90. If your assets are performing optimally, you should miss your expectations by 10%.

However, during your assessment if you notice a 20% gap, there is clearly another reason for underperformance. Once identified, this problem is in the hands of the operator to investigate and correct with his team.

4. How Can I Protect Against Missing Renewable Energy Asset Performance KPIs?

The best way to protect against missing asset performance KPIs (and maximize profitability while you’re at it) is to reforecast and question your assumptions frequently, especially when it comes to the weather.

The reality is that even asset management teams who are reforecasting right now have an easier time focusing on equipment performance metrics rather than resource performance metrics. I would argue that the best way forward, towards more meaningful KPIs, is to focus on weather and loss assumptions.

Most often, we end up using less than perfect techniques like triangulation to assess the impact of various properties on plant performance. However, there’s a big margin of error in these calculations.

Once the project has been in operations for a while, reliable equipment can help calculate metrics based on your own on-site numbers. With this highly accurate data, you can hone in on substantive weather-adjusted metrics, and in turn, better performance assumptions.

5. What Is the Difference Between Projects Underperforming in Year 1 and Year 10?

In the first year of operations for renewable energy assets—no matter if it’s solar, wind, or micro-hydro—your performance should be optimal. Equipment in this industry naturally degrades over time. So, in the first year, it’s important that you generate as much energy as possible because it’s likely the most you will ever generate.

By year 10, you’ll be producing less than you were in year one. So, if you underproduce in those first few years, your project’s cash flow projections will take a big hit. Consequently, making financial asset management difficult starting in year one— and you don’t want that.

Bottomline, if it’s the first year and you’re underperforming, you need to find the cause of the problem quickly.

6. What Steps Should I Take to Address Underperformance in Renewable Energy Asset Management?

To answer this question, let me bring the salient points of our discussion together.

To address underperformance, you should have this checklist top of the mind.

- Install reliable equipment and sensors to measure your on-site performance and weather as quickly as possible. This will give you a good understanding of your equipment and energy needs.

- Calculate your true weather-corrected performance values based on this data. This will tell you if the issue is your assumptions or your production.

- Narrow down the problem as best as you can (if the problem comes from your plant and not the weather) because searching for it can be a very expensive process.

- Eliminate as many factors as you can. Did the weather perform as expected? Are the meters calibrated? Are your sensors working? Now let’s boil it down inverter by inverter—which ones are doing badly and which ones aren’t?

- Calculate the ROI on fixing the issue. As an asset manager, you should pull in your operations, engineering and maintenance teams to figure out spending and saving numbers.

- Check your equipment proactively and regularly moving forward. Hire third parties to do flyovers or string-by-string analysis. The result? A definitive measure of your plant’s performance and year-over-year degradation.

Moving Forward…

No matter how advanced your financial models are, there will always be small deviations and missed factors.

Nonetheless, the more you can eliminate factors like fuel, resource and weather as variables in measuring renewable energy asset performance, the more confidence you’ll have in identifying opportunities for optimization within your plant.